PAPS (Pre-Arrival Processing System) and PARS (Pre-Arrival Review System) labels are essential components of the customs clearance process for cross-border shipments. These labels provide critical information to border agencies and help expedite the movement of goods across international borders. However, there are common challenges associated with PAPS and PARS labeling that can hinder efficient customs processes. This article explores these challenges and provides solutions to overcome them, ensuring smooth and timely customs clearance.

Challenge 1: Manual Data Entry Errors

Manual data entry poses a significant challenge in PAPS and PARS labeling. The risk of human errors, such as typos or incorrect information, can lead to delays, additional costs, and customs compliance issues. These errors can result in customs agencies rejecting the labels or questioning the accuracy of the shipment data.

Solution: Automated Data Transfer

Implementing automated data transfer solutions can help mitigate the risk of manual data entry errors. By integrating shipment management software with PAPS and PARS labeling systems, data can be automatically transferred to the labels. This reduces the reliance on manual input, ensuring accurate and consistent information on the labels. Automated data transfer minimizes human errors, expedites customs clearance, and improves overall labeling efficiency.

Challenge 2: Inconsistent Labeling Practices

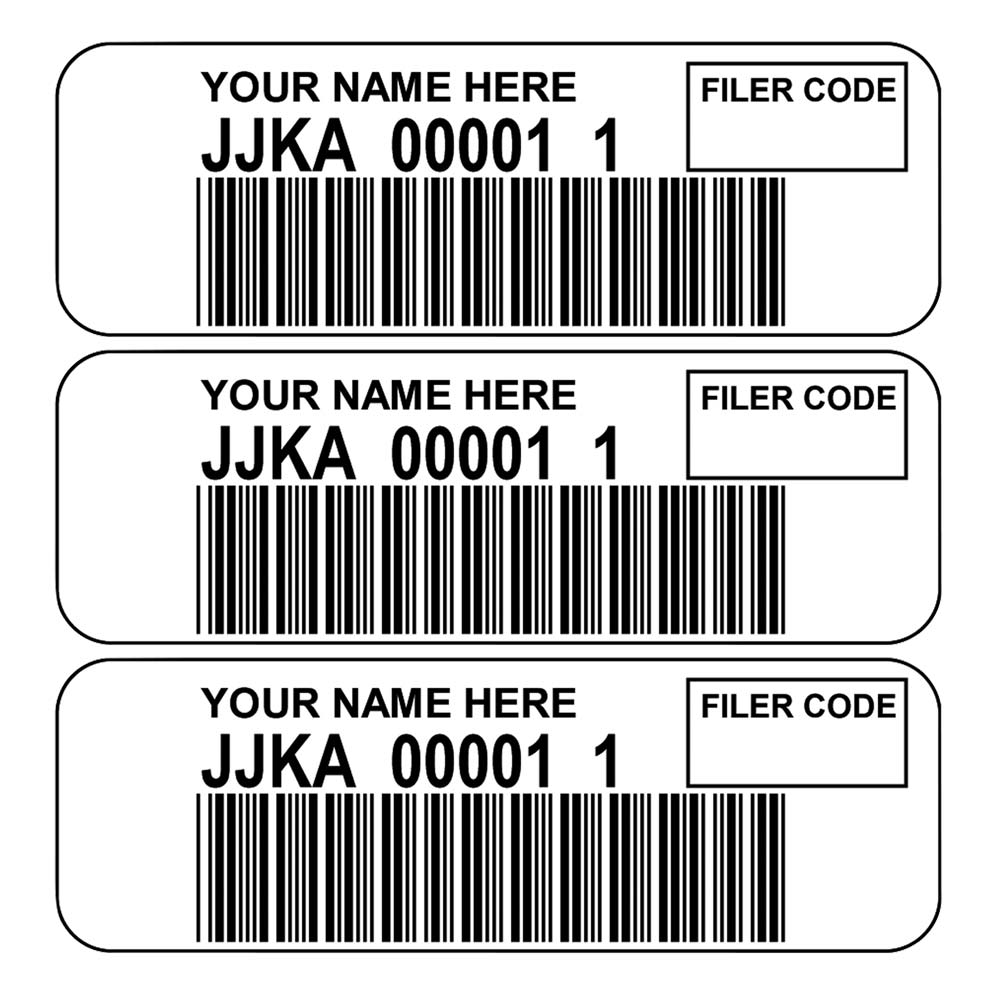

Inconsistent labeling practices across shipments can cause confusion and delays in customs processes. Customs authorities require standardized labeling formats and information to ensure smooth clearance. Inconsistencies in labeling can result in customs officials manually reviewing the shipments, leading to processing delays.

Solution: Standardization and Compliance

To overcome this challenge, companies should establish standardized labeling practices that comply with customs requirements. Implementing a comprehensive labeling policy that outlines the mandatory information, label format, and placement ensures consistency across shipments. Training employees and implementing quality control measures will help maintain compliance and streamline customs clearance.

Challenge 3: Changing Regulatory Requirements

Customs regulations and requirements are subject to frequent changes and updates. Keeping up with these changes and ensuring compliance can be challenging for companies. Failure to comply with new regulations can lead to shipment delays, penalties, and customs-related issues.

Solution: Stay Informed and Adapt

Staying informed about the latest regulatory changes is crucial for successful PAPS and PARS labeling. Regularly monitor updates from customs authorities and industry associations to ensure compliance with new requirements. Establish a process to review and update labeling practices in response to regulatory changes. Engaging with customs brokers or consultants who specialize in customs regulations can provide valuable guidance and help navigate complex compliance issues.

Challenge 4: Communication and Collaboration

Effective communication and collaboration among stakeholders involved in the customs clearance process are essential for smooth operations. Delays or lack of coordination in sharing labeling information can disrupt customs processes and lead to bottlenecks.

Solution: Streamlined Communication Channels

Establish streamlined communication channels with customs brokers, carriers, and other stakeholders to facilitate efficient sharing of labeling information. Implement electronic data interchange (EDI) or similar systems to exchange data seamlessly. Clear lines of communication, regular updates, and timely responses to inquiries ensure a collaborative environment and promote smooth customs clearance.

Challenge 5: Technology Integration

Integrating PAPS and PARS labeling systems with other supply chain management systems can be a challenge for some companies. Lack of integration between labeling systems and shipping or inventory management systems can lead to duplicate data entry, inconsistencies, and delays in sharing information.

Solution: System Integration and Automation

Investing in technology solutions that integrate PAPS and PARS labeling systems with other supply chain management systems is vital. Seamless integration allows for automated data transfer, reducing duplicate entries and ensuring data consistency. This integration improves workflow efficiency, minimizes errors, and enhances overall customs clearance processes.